15+ years in the industry.

There are various methods to accomplish the tasks, but what is provided here has been successful for me during my many years in this line of work.

Over the years, we have seen the same ‘bad practices’ being repeated – using incorrect techniques, tooling and procedures for Flange Tie-Ins.

Mostly, this is to do with a lack of understanding the flange engineering and therefore a lack of understanding as to how to produce a decent set of Flange Installation Aids to help divers Make Up Flanges safely and efficiently.

There is more than one way to skin a cat, as the cliché says, but what is detailed here is what has worked for us over the last 25 years or so.

More particularly, these procedures have been in regular use in Dive Task Plans on all of our construction projects since 2008. We have always maintained that preparation is about 90% (or more) of the diving & subsea work scope and contributes that same amount to a successful job in the water or on the seabed.

There are various methods to accomplish the tasks, but what is provided here has been successful for me during my many years in this line of work.

Since 2008, these procedures with the tooling have been utilised regularly in Dive Task plans on our construction projects. Preparation plays a crucial role in diving and subsea work.

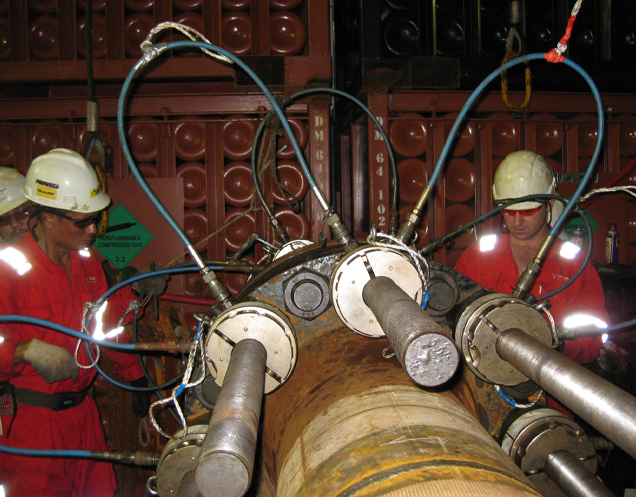

We expose and educate how to produce a decent set of Flange Installation Aids to help divers Make Up Flanges safely & efficiently.

The tools themselves are simple to use and understand. The tools are well made and consumable for engineering purposes so that within a short period of time the aluminum has dissolved completely from the RTJ (gasket) and from between the flanges.

The tooling & GIT has history & a proven record of installation & operation.