How Octopus Subsea Tooling™ Flange Spreader Paddles Improve Subsea Flange Alignments

Specialist Tools for flange alignment play a vital role in subsea engineering and flange make up. Whether you’re installing a pipeline, completing repairs or taking care of infrastructure on the seabed, precision is everything.

Misaligned flanges can lead to gasket failure, leaks and expensive downtime. That’s why the humble yet powerful flange spreader paddles can make all the difference. They are an essential part of the modern offshore spool tie in toolkit.

At Octopus Subsea Tooling™, we’ve developed industry-leading solutions to tackle these challenges. Focused on safety, simplicity and operational efficiency, we look to make life easier for busy engineers and divers.

Let’s explore how flange spreader paddles are used in subsea operations, why they matter, and how they support our flagship gasket insertion tool for total control over flanges.

The Challenge of connecting Subsea Flanges (Flange Tie-Ins)

Working with flanges on land is tricky enough. But underwater, the difficulties are only amplified. Operators must contend with limited visibility, restricted access and the constant threat of equipment failing on them.

Aligning two flanges perfectly on the seabed, requires more than brute force; it demands use of the right tools.

When flanges are misaligned, even by a few millimetres, gaskets cannot seat correctly. This results in poor sealing and increases the risk of leaks, especially in high-pressure systems. The consequence? Expensive delays, environmental hazards, and significant safety concerns.

What Are (manual) Flange Spreader Paddles?

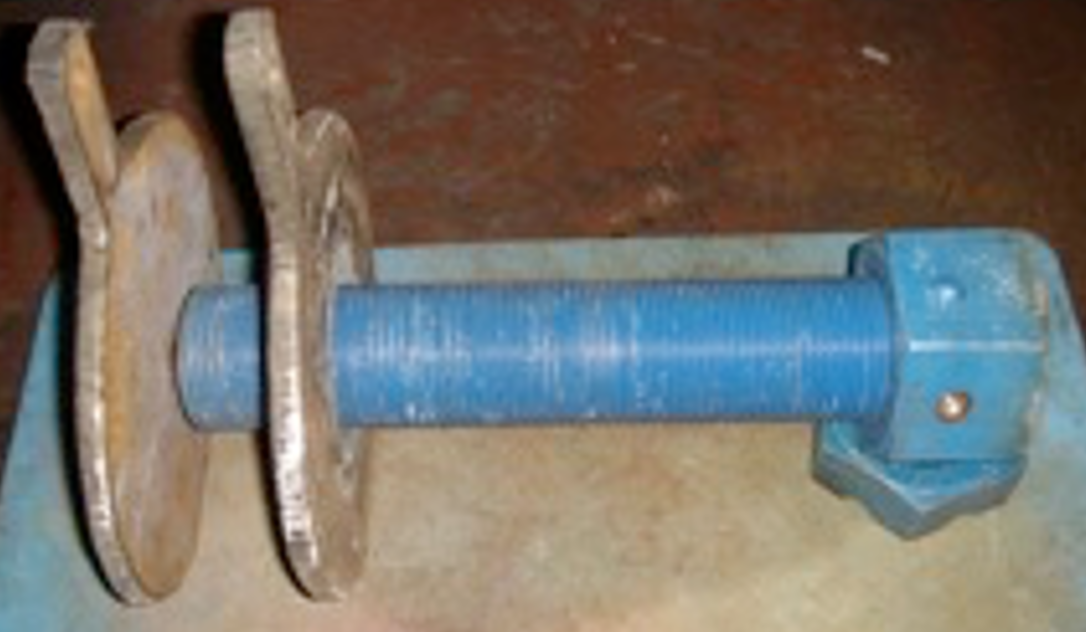

Flange spreader paddles are mechanical manual tools used to maintain a flange gap for ‘squaring’ up a flange while using hydraulic tooling to close the ‘open’ or wider side of the flange using hydraulic jacks. The paddles stop the narrow side of the flange coming together too quickly causing misalignment. In the trade this flange misalignment is called a ‘cheese’ as it looks pictorially like a slice of cheese.

The concept is simple: insert the paddles (as a set) into the narrow side of the flange, then apply gradual pressure to the open side or gap. Once the flange gap is even insert the RTJ gasket. When combined with our gasket insertion tool, the process becomes seamless.

Key Advantages of Using OST™ Flange Spreader Paddles

- Improved Safety Levels

Octopus Subsea Tooling™ flange spreader paddles reduce the need for using makeshift methods. This not only lowers the risk of injury but also prevents damage to flanges, bolts and sealing surfaces.

- Precision Alignment

Instead of forcing components into place, divers can create exact spaces / gaps using the flange spreader paddles. This level of control is vital in subsea work where alignment tolerance can be tight and time is money.

- Speed and Efficiency

Our tools are compact, lightweight and easy to deploy, in most cases they will be included in the subsea tooling basket.

- Minimal Downtime

By reducing the effort and time required to align flanges, operations are faster, saving both OPEX and labour hours.

Integration with Our Gasket Insertion Tool

What truly sets Octopus Subsea Tooling apart is how our flange spreader paddles work in tandem with our flagship gasket insertion tool.

Changing traditional gaskets offshore often requires partially disassembling the flange joint, creating unnecessary risks and delays. Our tool allows for safe insertion of gaskets into depressurised systems, without full disassembly.

Here’s how the system works:

- Deploy the flange spreader paddles to create a safe and even gap between the flanges.

- Stabilise the alignment using controlled tension or alignment tools as needed.

- Insert the new gasket cleanly and accurately using the gasket insertion tool.

- Remove the paddles and re-torque the bolts, ensuring a perfect seal and alignment.

This solution eliminates common issues in offshore maintenance: pinched gaskets, uneven bolt loading, or distorted flange faces. The result is a safer, faster and more effective gasket change.

Built for Harsh Conditions

Our flange tools are engineered for survival in the most punishing environments. Every flange spreader paddle is:

- Made from superior metals

- Tested to exceed industry standards

- Compact and modular, to be able to carry a full toolkit with minimal bulk

- Compatible with hydraulic or manual actuation, depending on job scope and crew preference

All our designs reflect real-world subsea experience. We understand that divers need tools that are safe to use and work: no fuss, no failure.

Who Uses Our Flange Tie In Tools?

Our flange alignment solutions are trusted by:

- Offshore oil & gas operators

- Subsea diving contractors

- Renewable energy developers

In the subsea construction environment, Octopus Subsea Tooling™ equipment is helping to make subsea spool tie in and flange make up, safer, faster and smarter.

Closing the Gap, Literally and Figuratively

In subsea installations, getting flanges aligned isn’t just a technical task: it’s a mission-critical operation. Poor alignment compromises safety, disrupts work and inflates costs.

With Octopus Subsea Tooling™ flange spreader paddles and gasket insertion tools, divers can solve flange ‘cheese’ misalignment with confidence. Our tools are compact, intuitive and field-tested, bringing engineering expertise to the unpredictable world of spool flange tie ins.

Looking to improve your subsea flange tie in procedures offshore?

Explore our full range of subsea installation aids. Or contact the Octopus Subsea Tooling™ team for a custom solution tailored to your operation.