Information

- Essentially these large pieces of equipment can make or break a good Flange Up and Tie-In.

- Must be designed for the conditions on the seabed with decent-sized mud-mats to allow a suitable footprint on the seabed.

- The top of the PHF must have suitable pad eyes to accommodate the shackles and Chain Falls required for the job.

- The lifting rigging must be attached to correctly made and certified pad-eyes.

- To assist the divers in attaching and releasing these lifting slings into and from the crane hook, floatation must be added.

- The side bracing of the PHF must be stiffened, suitable to reduce flex in the frame as much as possible.

- At each end of the cross brace pad-eyes are welded to accommodate side-pull come-a-longs. Also in this area tool baskets can be added for extra equipment storage that might be required by the divers.

- Always ensure that a safety sling is provided for the divers to choke around the pipeline once it is in position on the Chain Fall.

- Chain Falls have been known to ‘run’ and if a diver were to be under the pipeline in such an incident, a major

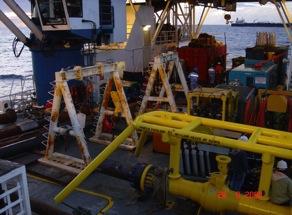

Pipe Handling Frames – Manual Type – Showing Top Section Flanges

- This type of PHF Construction allows for easier transportation of the PHF as it can be unbolted at the flanges.

- The diagonal struts may or may not be required as an engineering advantage.

- This design of PHF allows for the inclusion of extension ‘pup’ pieces to add additional height if not enough lift on the flange or pipeline is achieved or if the PHF is sinking into the seabed.

- It also allows the PHF to be broken down on the seabed and recovered more easily if it becomes stuck due to seabed mud suction.

CONTACT US